Product Overview: Application for Cement Machinery

The Application for Cement Machinery is a critical industrial solution used extensively across cement manufacturing plants for batching, conveying, mixing, and material handling. This advanced system ensures efficient processing and consistent output while minimizing manual intervention. With increasing demand for automation and precision in the cement industry, high-performance machinery applications have become essential to maintain quality and productivity.

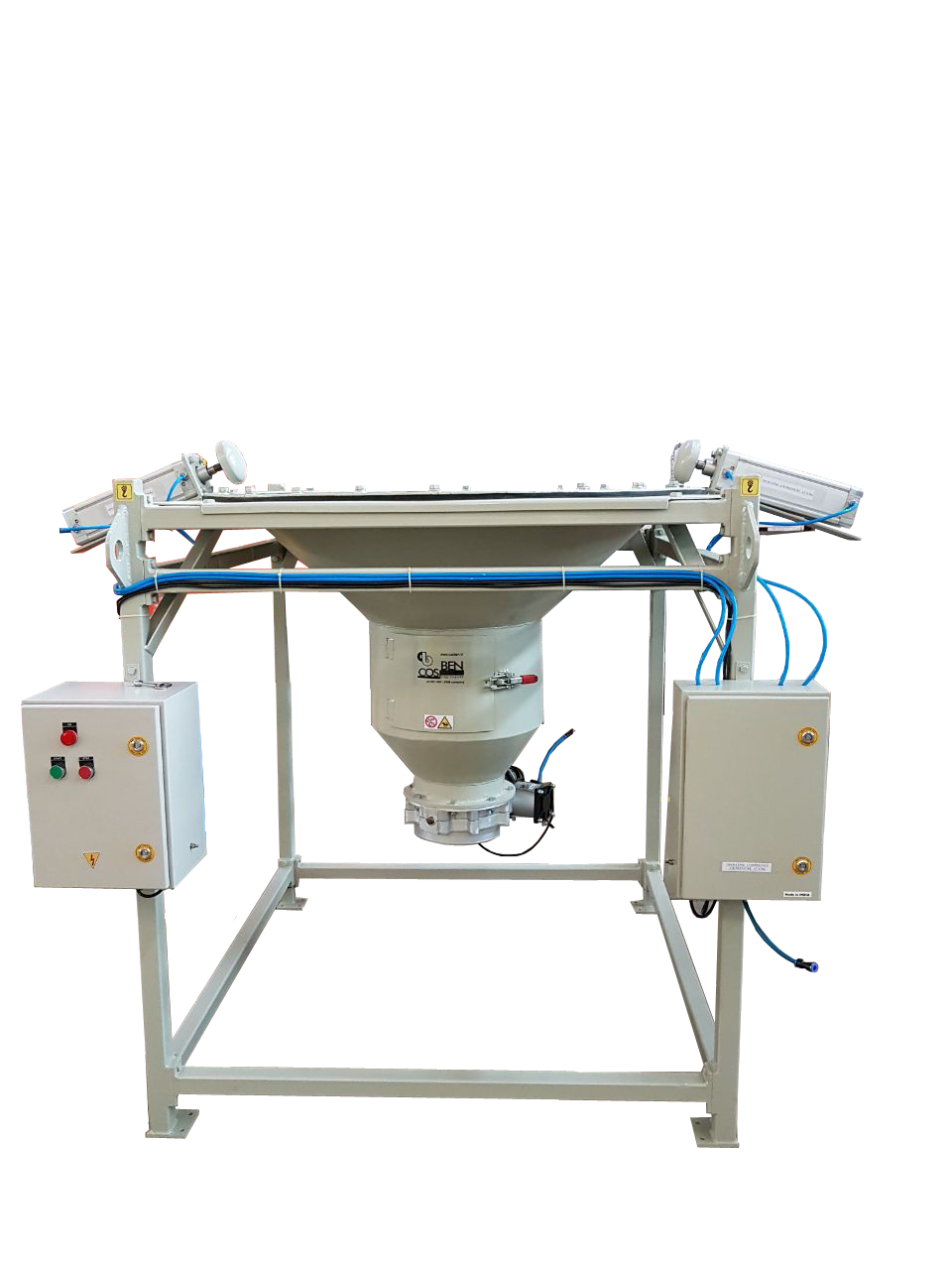

Efficient Material Batching Systems

Accurate batching is the foundation of high-quality cement production. The Application for Cement Machinery automates the batching of raw materials, including limestone, fly ash, gypsum, and additives. This ensures consistent material ratios, reduced wastage, and enhanced product uniformity. Equipped with precision sensors and control units, the system greatly improves operational accuracy.

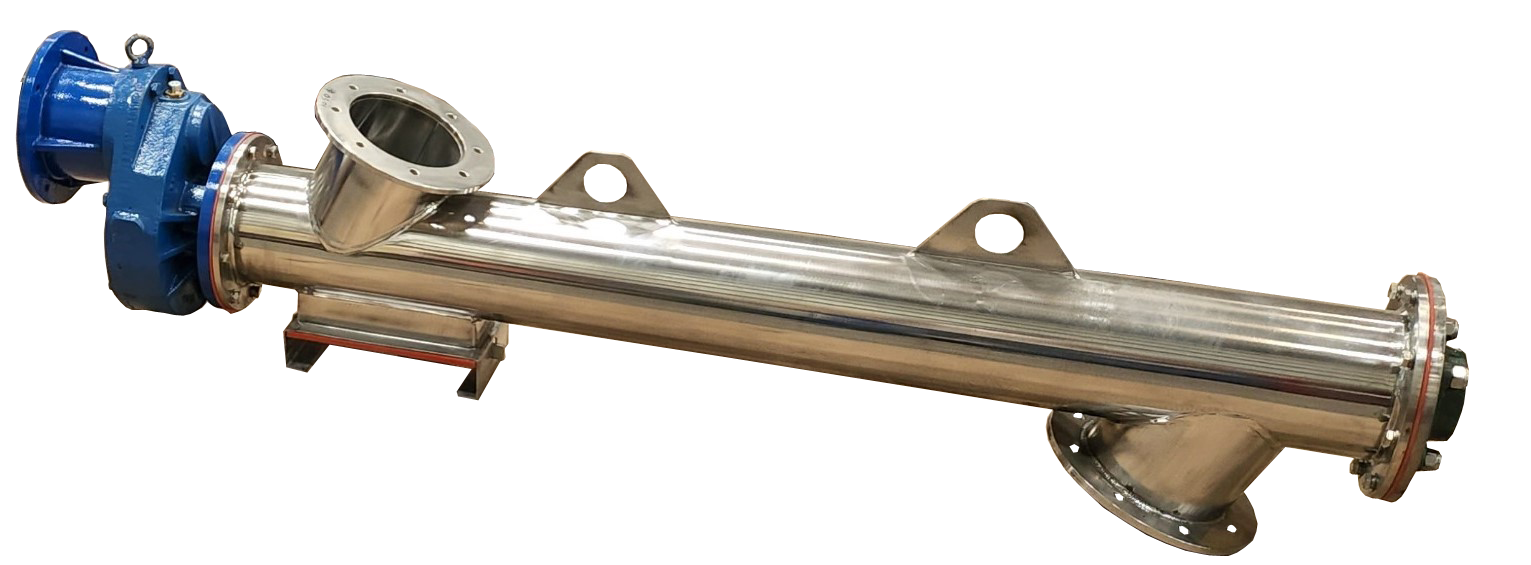

Advanced Conveying Solutions

Conveying plays a central role in transporting raw materials and finished products within cement plants. This machinery application includes robust screw conveyors, belt conveyors, and pneumatic conveying systems for efficiently handling bulk powders. The equipment offers smooth, continuous flow, minimized spillage, and reduced downtime due to its rugged construction.

High-Performance Mixing Applications

Uniform mixing is essential to achieve the desired cement grade and strength. The Application for Cement Machinery supports advanced mixing operations with specialized mixers that thoroughly blend materials. These mixers are equipped with high-durability components, automated control systems, and energy-efficient mechanisms to optimize mixing cycles and ensure consistent output.

Reliability and Safety

These applications prioritize operator safety, dust control, and system reliability. Safety features like overload protection, enclosed systems, and automated emergency stops safeguard operations and improve plant efficiency. Additionally, the machinery is designed to withstand abrasive materials, offering long service life and low maintenance requirements.

About Saksham Industrial Engineers & Product Availability

Established in 2011, Saksham Industrial Engineers is a trusted supplier and technical consultant specializing in innovative powder-handling and cement-industry solutions. Backed by strong global partnerships and expert service support, the company provides high-quality applications tailored for modern cement plants. Saksham Industrial Engineers is one of the reputed Manufacturers and Suppliers of Cement Machinery applications in Ludhiana, offering durable, reliable, and cost-efficient systems to support batching, conveying, and mixing operations across the cement sector.

Application For Cement Machinery

Designed to ensure seamless performance and maximum productivity.

Available in Ludhiana

₹75,000.00

Inclusive of all taxes

Available in Different Designs

- Precision batching and automated controls

- Heavy-duty conveying components for bulk powder handling

- Energy-efficient and durable mixing systems

- Advanced safety mechanisms and dust-control design

- Customizable configurations for different cement plant needs

Contact Product Information:

Call us for detailed product information, customization options, and bulk pricing.

Product Description

Technical Specifications

| Material Type | Cement, fly ash, gypsum, additives |

| Batching Capacity | 100 kg – 5000 kg (customizable) |

| Conveying Type | Screw, belt, pneumatic |

| Mixing Speed | 20–60 RPM (depending on configuration) |

| Motor Power | 2 HP – 50 HP |

| Construction Material | Mild Steel / Stainless Steel |

| Automation Level | Semi-automatic / Fully automatic |

| Control System | PLC-based |

| Operating Temperature Range | Up to 150°C |

| Power Supply | 230V/415V, 50Hz |

Product Benefits

-

Ensures consistent product quality

-

Reduces operational costs

-

Minimizes manual labor and human error

-

Increases production efficiency

-

Enhances workplace safety

-

Lowers maintenance frequency

-

Supports continuous and stable operations

-

Improves energy utilization

-

Allows seamless integration with existing plant systems

-

Extends equipment lifespan

Quality Assurance

Every product undergoes rigorous quality checks and comes with comprehensive warranty coverage.

Frequently Asked Questions

It is used for batching, conveying, and mixing raw materials in cement production.

Yes, it is built with abrasion-resistant components suitable for cement and powder materials.

Yes, it can be integrated with existing batching or conveying systems.

Typically 8–12 years with proper maintenance.

Yes, the system comes with PLC-based automation options.

The company was established in 2011.

They serve cement, chemicals, food, pharmaceuticals, and other powder-handling industries.

Yes, full installation and technical support are provided.

Yes, Saksham Industrial Engineers offers fully customized machinery applications.

The company is a leading supplier based in Ludhiana.

Capacity, automation level, material build quality, and additional features.

Periodic inspection, lubrication, and cleaning—usually low-to-moderate.

Batching systems, conveyors, and mixing equipment are essential.

Automation improves accuracy, reduces waste, and enhances plant efficiency.

Prices generally start from ₹75,000 depending on size and configuration.