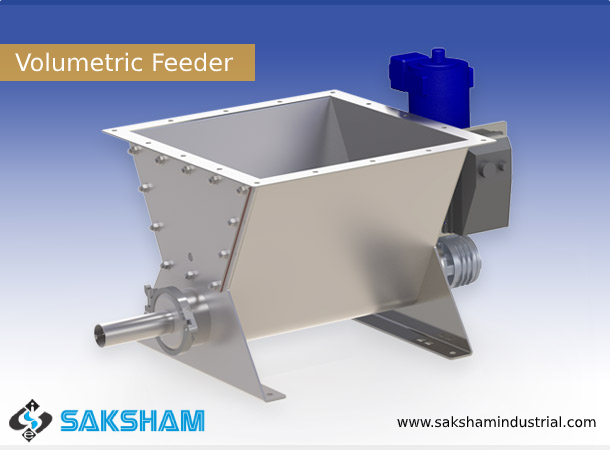

Volumetric feeder To use a volumetric feeder, the user must know the rate at which an ingredient must be dispensed into a process and how much volume that weight represents. To set the rate in a volumetric feeder, the user turns on the feeder auger and begins catching samples in a container for a timed period. After each catch, the user weighs the sample and then adjusts the auger speed, up or down, until the feeder delivers the correct amount of the ingredient into the sample container. The sampling process must be repeated each time that that there is a change in bulk density or a change in the ratio of the ingredient in the process.

Attributes of the volumetric concept are as follows:

-

Cannot automatically compensate for material density variation

-

Other factors affecting calibration or Sensitive to material build-up

-

No direct measurement of material throughput

- Limited turn-down, insensitive to system non-linearity

- No innate detection of material supply interruption

- Regular re-calibration required

- Limited performance accuracy potential

Gravimetric feeders represent a significant improvement over volumetric feeders. They utilize a computer and a load cell that continuously records the weight of the feeder and its contents. When the user inputs a given dispensing rate, the computer automatically calculates the rate and begins releasing the ingredient into the process. Simultaneously, the load cell reports the loss-in-weight of the feeder and remaining material, enabling the computer to continuously calculate and control the amount of material being dispensed.

Attributes of the gravimetric concept are as follows:

-

Direct measurement and control of feed rate and close loop control

-

Automatically compensates for material density variations

-

Insensitive to material build-up on metering element

-

Direct measurement of material rate

-

Automatic detection of material supply interruption

-

No calibration required

-

High performance accuracy potential

Advantages and disadvantages of gravimetric feeder and volumetric feeder

The advantages and disadvantages of gravimetric feeder and volumetric feeder can be concluded in the following way:

Gravimetric feeder

Advantages

-

Self-adjusting

-

100% control over your product quality

-

Easy to operate

-

Monitoring and reporting options

-

Higher saving on expensive additives

-

Fluctuations in density do not effect outcome

-

In-sensitive to material build-up

-

Automatic detection of material supply interruption

-

Accurate dosing cylinder

-

Stepper motor speed from 0.1 up to 200 rpm

Disadvantages

-

Relatively more expensive than a volumetric feeder

Volumetric feeder

Advantages

-

Relatively low priced dosing system

-

Accurate dosing cylinder

-

Stepper motor speed from 0.1 up to 200 rpm

Disadvantages

-

Manual re-calibration required

-

Limited control over your product quality

-

No monitoring and reporting options

-

Cannot automatically compensate for fluctuations in density

-

Sensitive to material build-up

-

No automatic detection of material supply interruption

Recent Comments